Advantages of industrial flooring for cooling chambers

- It retains all the advantages and resistance of the industrial floor

- Energy saving for cooling chambers

- Stable temperatures

- Proper preservation (or freezing) of the products

- Minimizes cooling losses in case of chamber failure or power failure

Ask our offer and prices for industrial floor

Contact us. We give solutions. Simply!

- Fill the contact form

- Call us at the following telephone numbers: 210 62 55 780, 22 210 79 950

- Come to our technical departments in Athens and Chalkida

- Visit our Facebook and Twitter pages and send a message

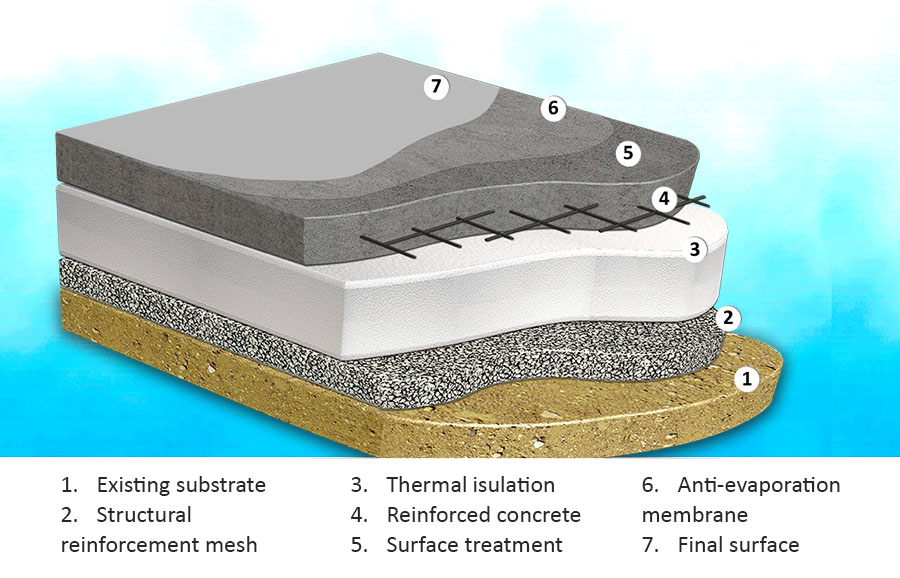

Technical description for the construction of industrial floors

How to install thermal insulation to industrial floors

Before the placement of the reinforcement and concrete (see the construction way of an industrial floor), special thermal insulating panels of extruded or expanded polystyrene with very high mechanical strengths are placed.

The thickness is defined upon agreement with the owner according to the cooling (or freezing) needs or according to the thermal insulation research(and the temperatures that the refrigerator will operate)

The minimum recommended thickness is 10cm, regardless of the temperatures the chamber will operate .Adhesive is made using a special anti-mold glue. After thermal insulation of the floor, next is the industrial flooring process.

If there is already a substrate (already formed industrial space - concrete slab), the following pre-work steps are carried out before the laying of the thermal insulation plates and the final industrial floor.

Substrate

All surfaces must be free from dust, clay and loose materials. The cleaning will be carried out with pressurized water spray, which will achieve complete surface cleaning.

Any cracks, loose materials, wooden wedges will be mechanically removed with an electric hammer at a depth of at least 2 cm and will be sealed with a suitable fiber-reinforced cementitious material.

The working joints of the concrete to be coated will be expanded in V-shape and sealed with the same fiber-reinforced cementitious material.