Advantages of the Energy Plus Pylotis system

- Thermal-insulation and waterproofing at the same time

- Huge energy savings

- High waterproofing

- Very good transpiration

- High quality final paint

- Choose color from thousands of available shades

- Resistance even in extreme weather conditions

- Low maintenance costs

- Multi-year written warranty.

- It can be applied to all types of masonry

- Trust Andreoy Insulation SA as well as thousands of others. It applies:

- Quality Control System ISO 9001: 2015 & Environmental Management System ISO 14001: 2015

- Occupational Health and Safety Management System ISO 45001:2018

- All the construction crews of Andreoy Insulation SA consist of:

- Civil Engineers

- Certified technicians on Insulations / Insulators by ESYD in accordance with the International Standard ISO / IEC 170244

- Specialized and certified technicians according to DIN CERTCO

Ask our offer and prices for Energy Plus Pylotis system

Contact us. We give solutions. Simply!

- Fill the contact form

- Call us at the following telephone numbers: 210 62 55 780, 22 210 79 950

- Come to our technical departments in Athens and Chalkida

- Visit our Facebook and Twitter pages and send a message

Andreoy Insulation SA is available in Athens, Attica, Chalkida, Evia, Thiva and Viotia.

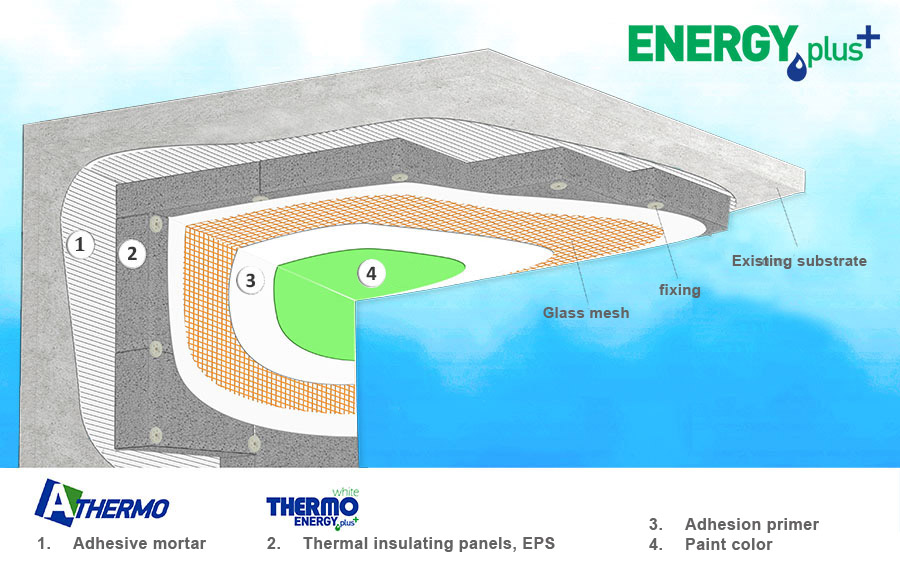

Technical description of Energy Plus Pylotis system

Mounting surface

Cast concrete, can generally be applied to almost any surface.

Thermal insulation

Thermal insulation material: EPS THERMOENERGY PLUS white ETICS, λ = 0.035, certified for installation in external thermal insulation systems. The thickness of the insulating material is selected upon agreement with the owner

Way of placement of the thermal insulation material

Fastening with bonding and reinforcing fiber reinforced material, high adhesion and elasticity, A-THERMO and then mechanically fastening with a double-headed plug. Placement of special parts at all the points where the thermal insulation material has been mechanically fastened. Assembly of all joints of the insulation material with low-swelling polyurethane foam. With this methodology, we provide almost zero thermal bridges and thermal losses.

Sanding and finishing the entire surface of the external thermal insulation with a suitable rotary electric sander

We need to create and deliver a flawless and smooth surface!

System reinforcement

- Reinforcement of beams with a corner beads and water dripper

- Reinforcement of all corners of the building with a corner beads

- MASTERNET 160 reinforcing glass mesh

- laying of reinforcement and full boxing of mesh with fibrelated mortar.

Primer adhesion

Application with acrylic water-soluble primer. It is recommended to paint it in the color of the final plaster.

Final acrylic paint

Final protection with acrylic-based paint. It can be painted in our technical department's machinery in the shade of your choice!