Advantages of Brushed Floors

- High resistance to pressures and loads

- They do not get damaged even with heavy use

- Not affected by extreme weather conditions

- It's not slippery

- No appearance of cracks

- Suitable for industrial spaces where anti-slippage is required

- Suitable for tilt parking areas

- Construction time is very short

- Easy maintenance

- Durability

- Can be painted during construction

Ask our offer and prices for brushed floor

Contact us. We give solutions. Simply!

- Fill the contact form

- Call us at the following telephone numbers: 210 62 55 780, 22 210 79 950

- Come to our technical departments in Athens and Chalkida

- Visit our Facebook and Twitter pages and send a message

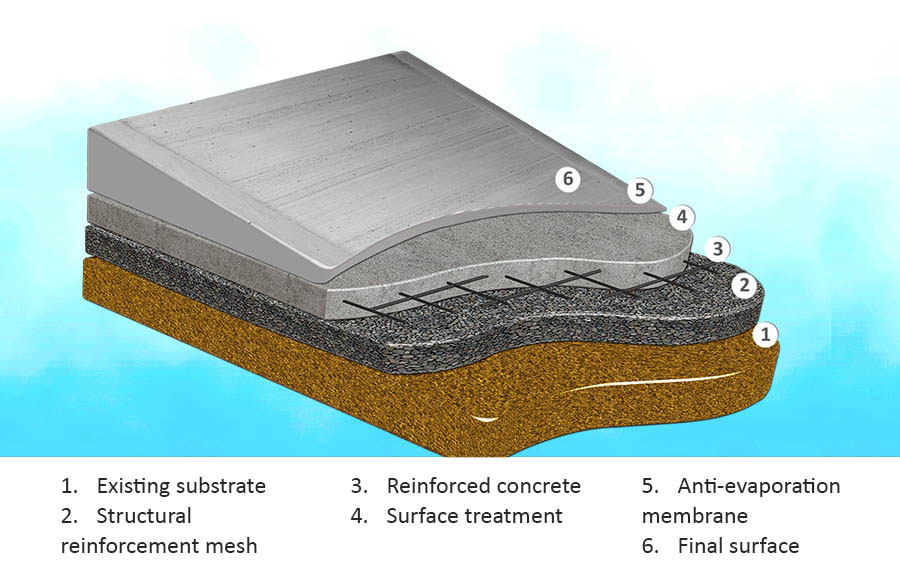

Technical description for the construction of brushed floors

Existing substrate

The space in its original form

Plate of concrete or padding.

It is necessary to have a healthy and strong substrate, since the loads to be accepted are large enough. If it does not already exist, the easiest way is to make a layer with crushed material and pebbles, then a final 20cm thick sublayer with graded material 3A.

Structural reinforcement mesh

Double mesh T131 placed prior to concreting for additional reinforcement of the concrete, after delimiting the space to be applied to the industrial flooring (molding)

Reinforced concrete

It is very important for our concrete to be of excellent quality, since it depends on the strength of the industrial floor. For the manufacture of industrial flooring, we need necessarily new concrete of a thickness of at least 10 cm. The concrete is laid through a high-performance laser screed machine, which is fully automated, controls and adjusts the level of the concrete using a laser.

Surface treatment

Grinding and hardening of the final surface with quartz sand of fine particle size. With the completion of the concreting and once the surface has matured sufficiently to make it easy, the quartz sand is incorporated with the use of a special broom. The final surface is non-slip and very tough.

Anti-evaporation membrane

Maintenance of concrete with spray of anti-evaporation membrane

Final surface

In the case of the industrial floor and in accordance with ELOT EN concerning the floor coverings, expansion joints are mandatory for the contacts with the vertical elements (walls, columns) and canvas for 20 to 25 m² with lengths of not more than 6 meters